Predicting Springback In Sheet Metal Forming

Sulaiman khan frans coenen clare dixon subhieh el salhi department of computer science university of liverpool united kingdom fmskhan coenen cldixon salhig liverpool ac uk.

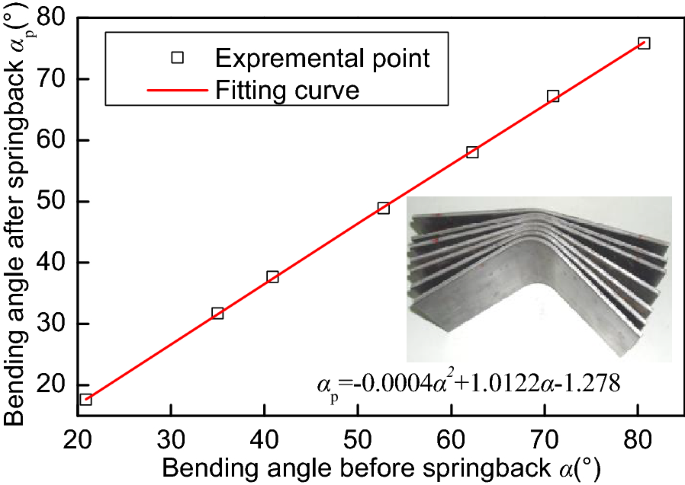

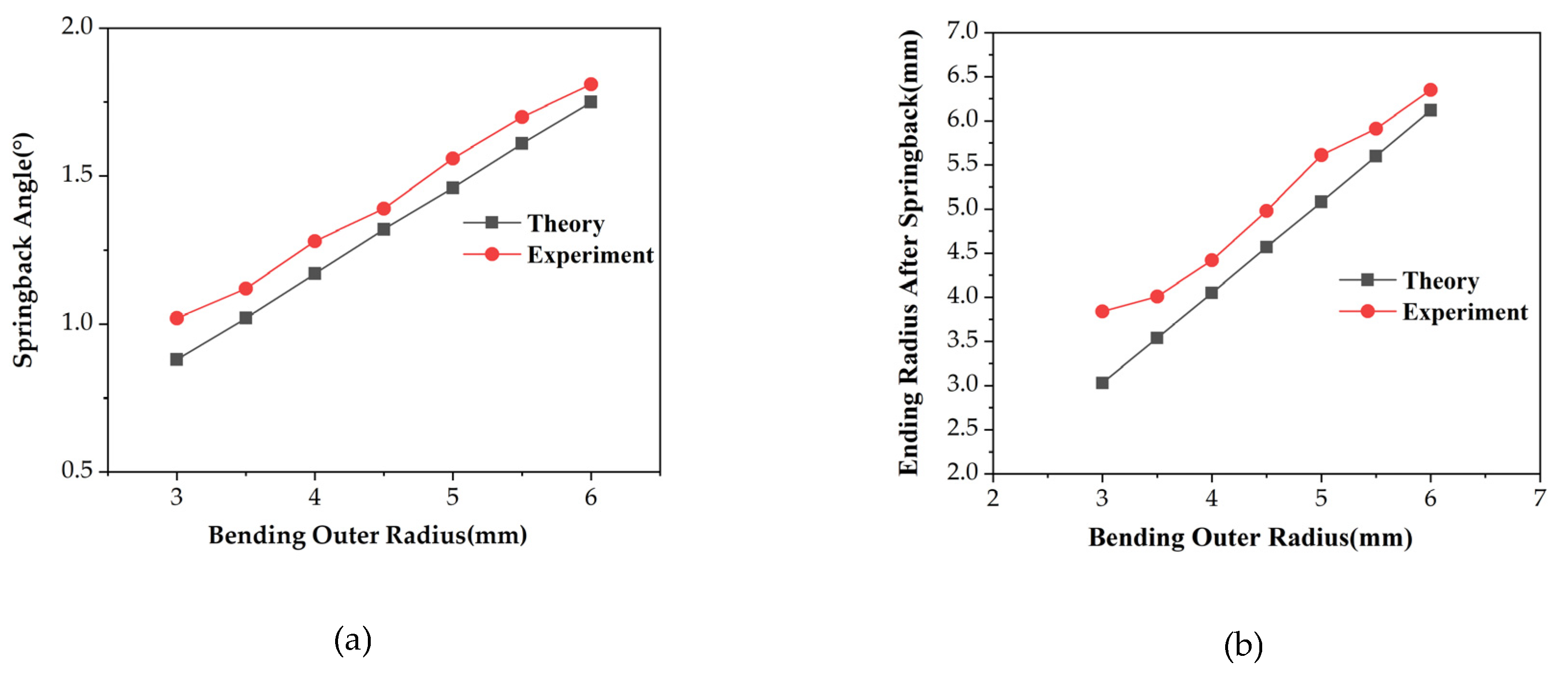

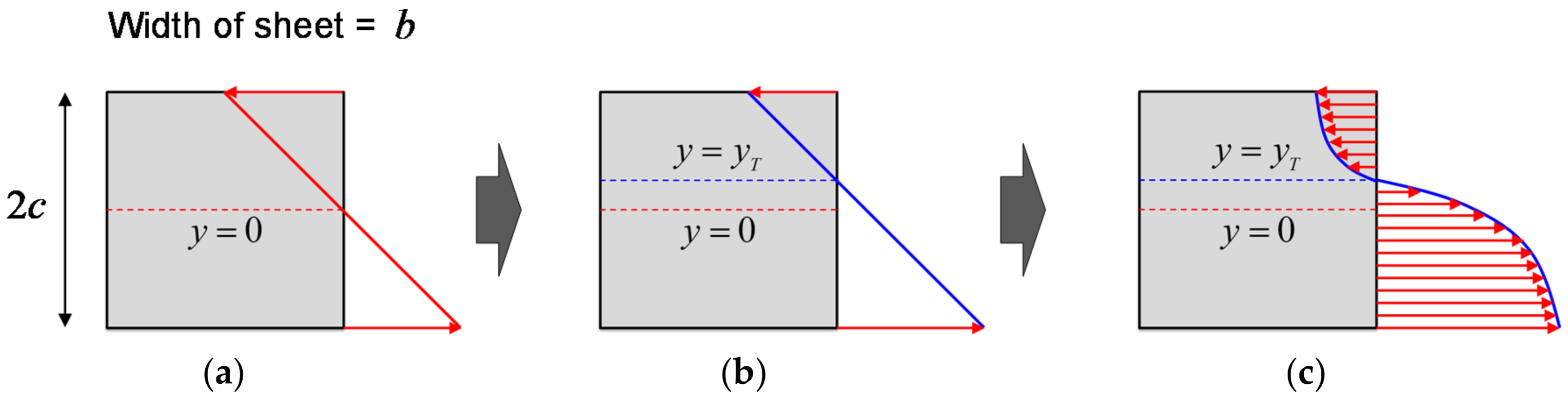

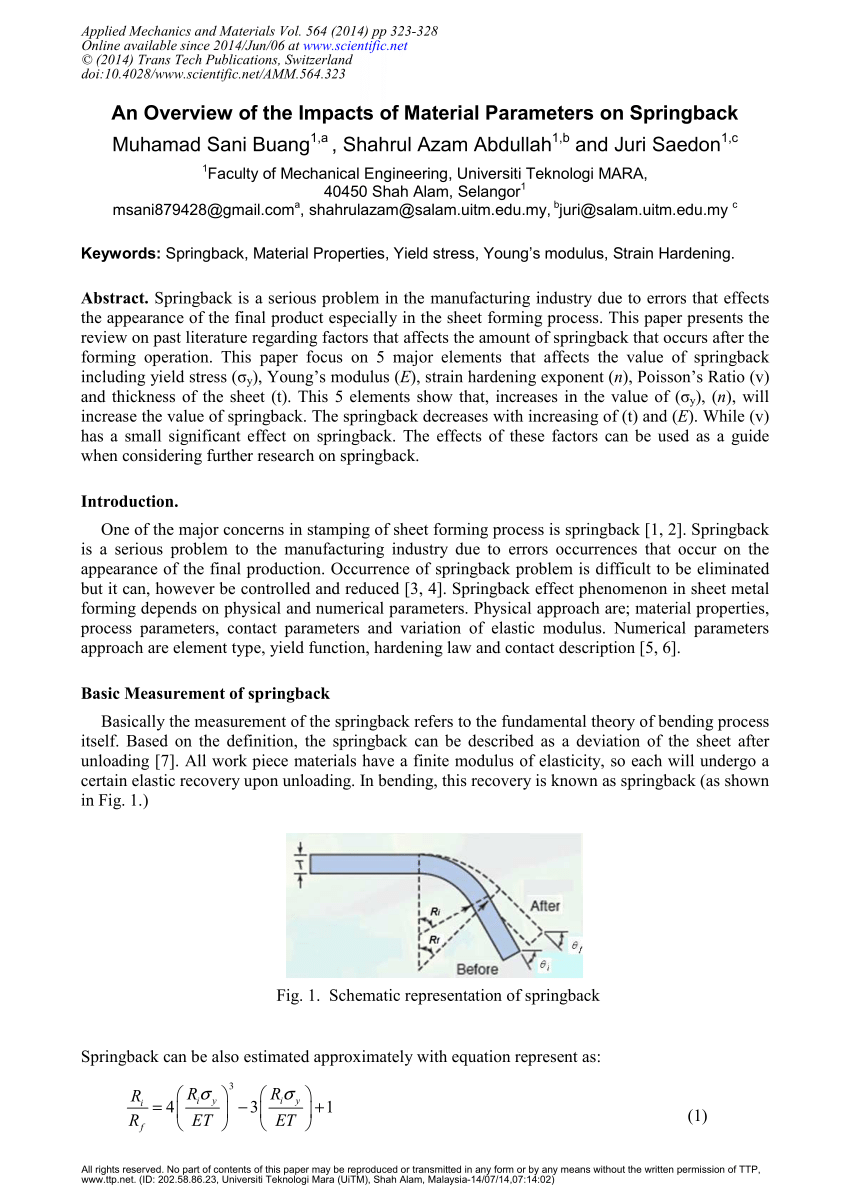

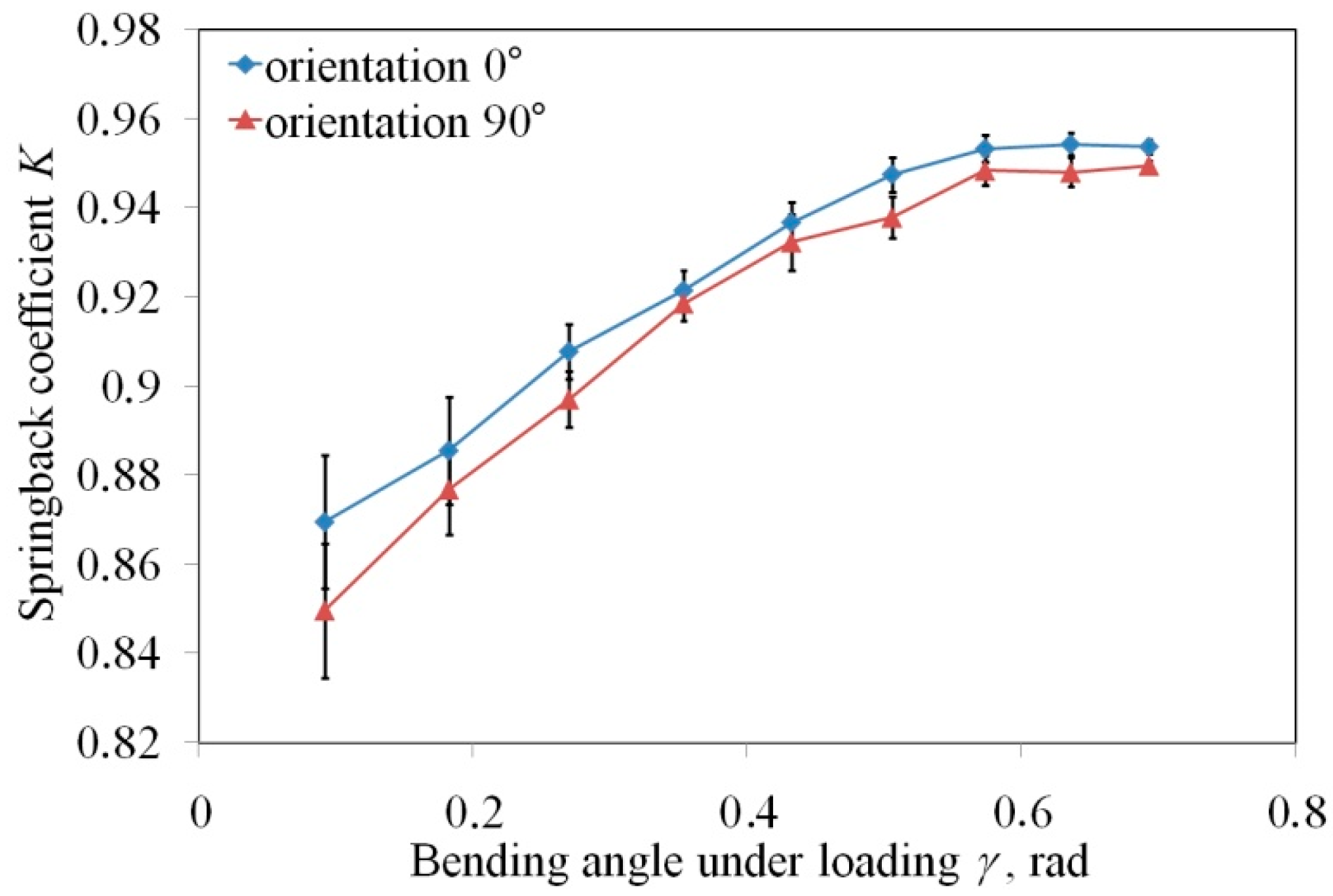

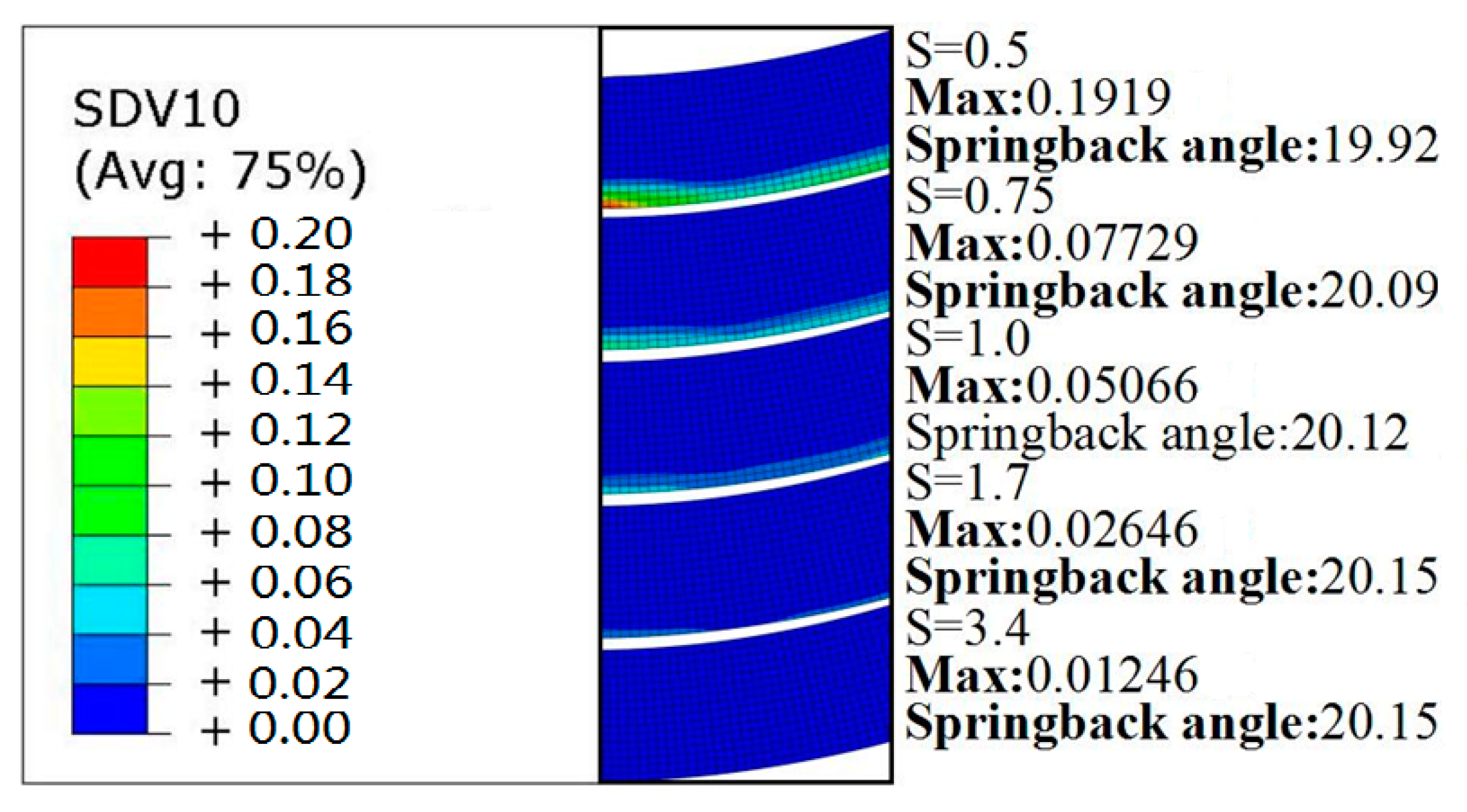

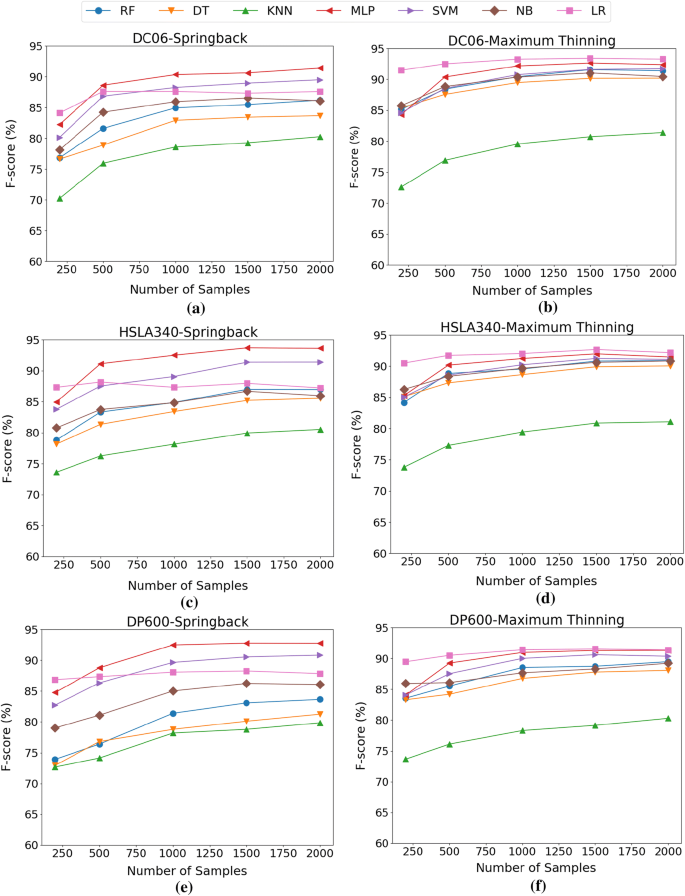

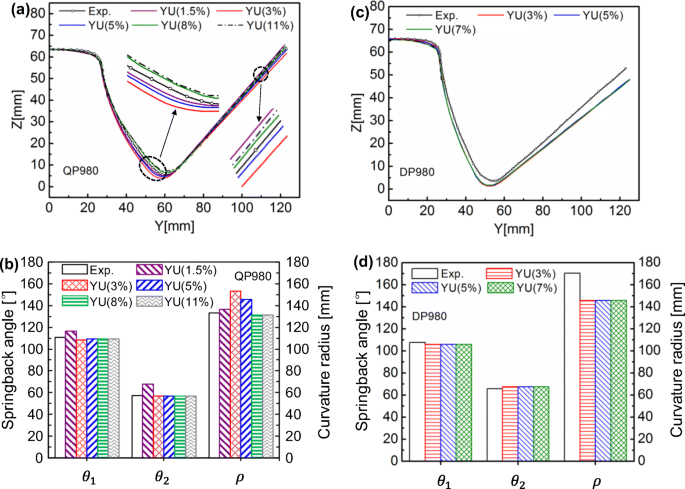

Predicting springback in sheet metal forming. The results have been representing the effect of different value of svg style. Springback can be defined as an elastically driven change of shape of the deformed part upon removal of external loads. Using the deformation theory of plasticity formulation of the problem and spring back ratio is derived using modified ludwik stress strain relationship with tresca and von mises yielding criteraia. Classification based 3 d surface analysis.

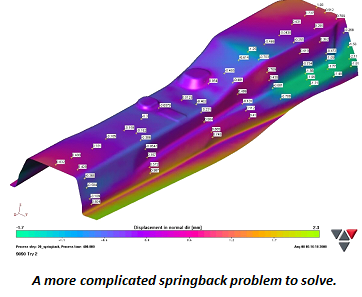

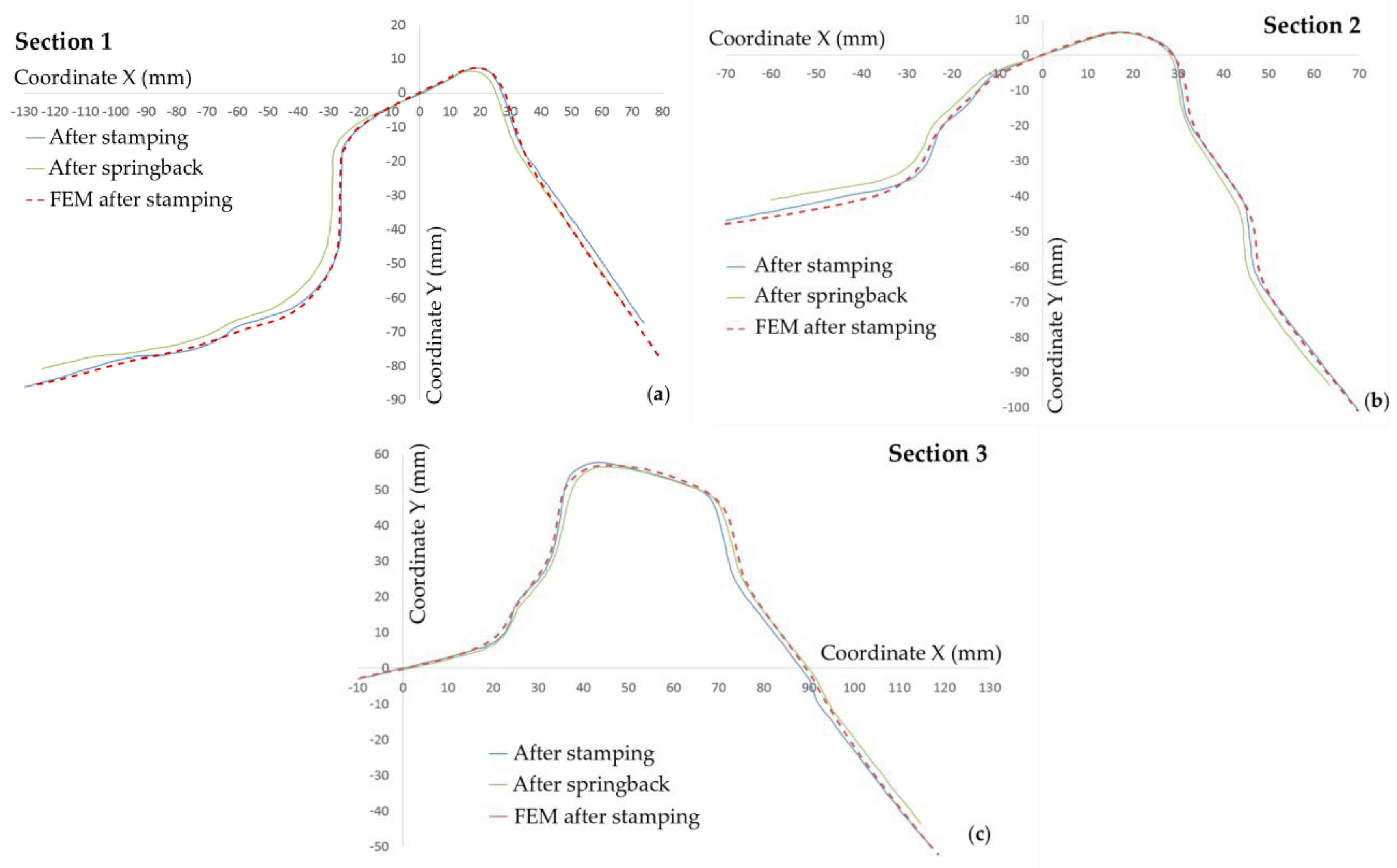

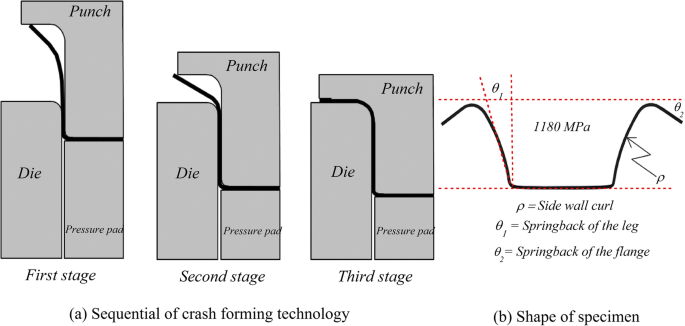

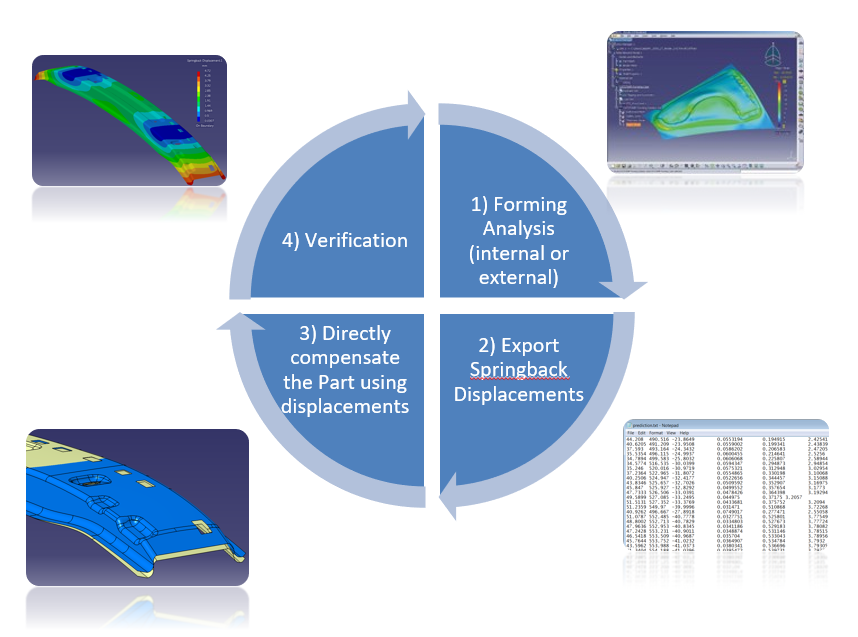

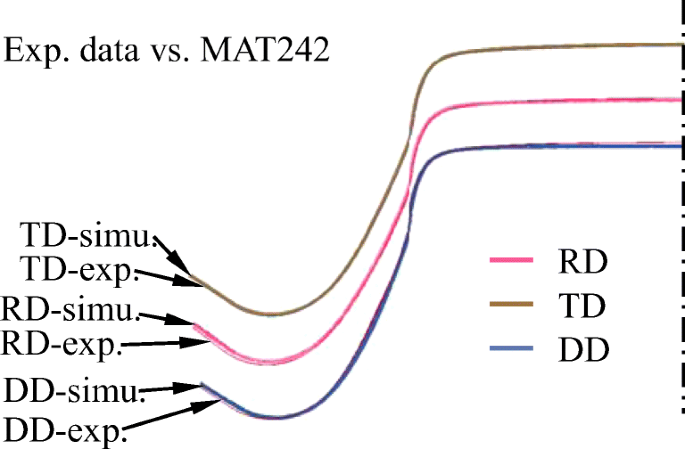

To act as a focus for the work the prediction of springback within the context of sheet metal forming is considered where springback is a form of deformation that occurs in a non uniform manner across a manufactured 3d surface as a result of the application of some sheet metal forming process. Predicting springback in sheet metal forming m. In this work a coupled explicit to implicit finite element procedure is outlined for predicting springback deformations in sheet metal forming processes. Note predicting springback will never perfect a perfect science.

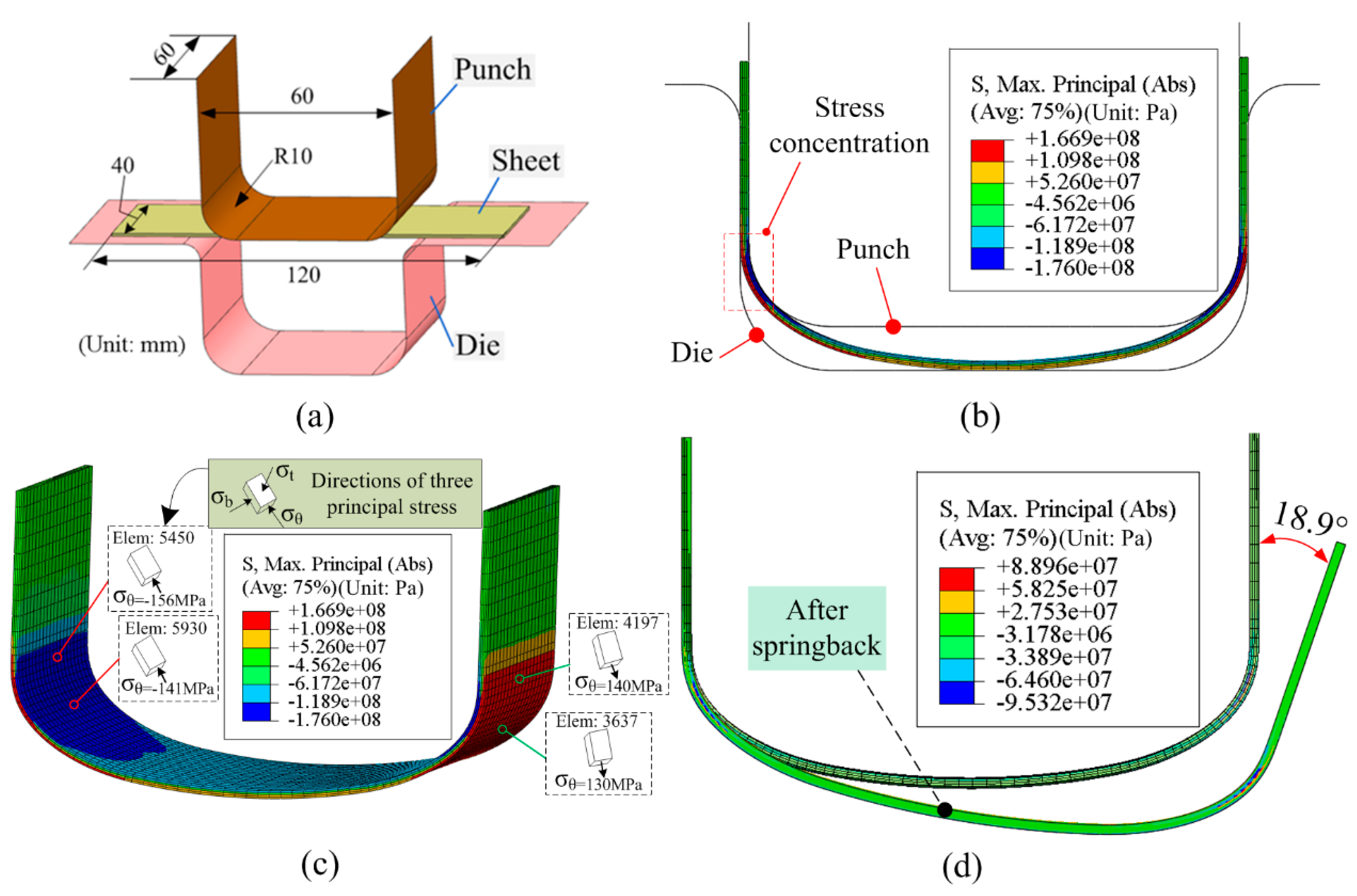

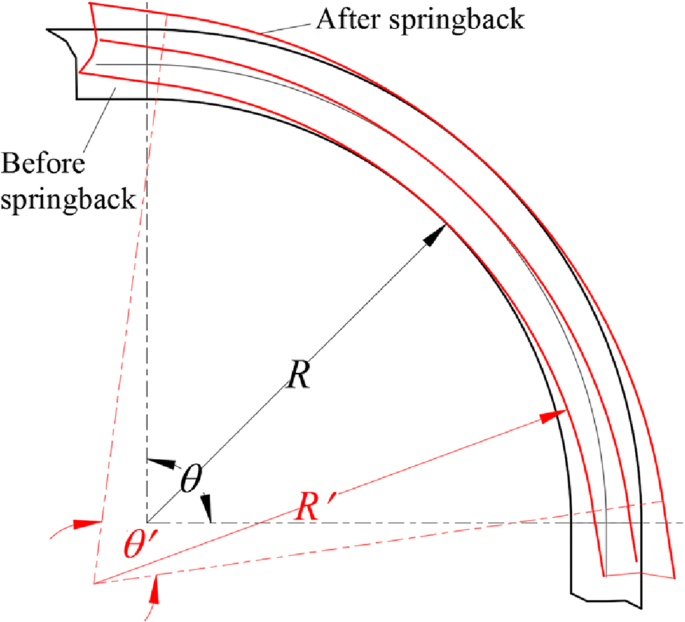

The objective is to predict springback the deformation that results as a consequence of the application of a sheet metal forming processes. When the material is then released from the pressure of forming stresses within the bend tension outside the compression inside causes the bend angle to open and the radius to open. Springback which is the elastic recovery of the non uniformly distributed stresses in a deformed part after the forming load is removed is one of the most critical issues in sheet metal forming. The springback properties of sheet metals make the design of forming dies extremely difficult.

This phenomenon results in a deviation of the real product geometry from that defined in the design. This paper deals with the springback analysis in sheet metal forming using modified ludwik stress strain relation. Finite element simulation of sheet metal forming is a well established tool which is used in industrial practice to evaluate geometrical defects caused by elastic springback.