Processing Roofing Granules

We provide a wide range of thermal processing equipment for all of your roofing granule production needs including pre heaters combustion chambers rotary dryers rock dryers rotary kilns and rotary coolers.

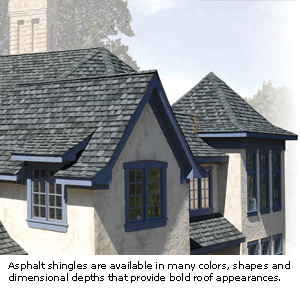

Processing roofing granules. As an aesthetic treatment of end laps and side laps on granule surfaced built up and modified bitumen membranes mineral shield roofing granules provide a multi faceted design and light reflective construction that adds dimension and depth to membrane products. Get pricing and availability. While roofing granules may not look like much more than rocks they are actually a highly engineered product the result of advanced processing techniques that work to create a premium roofing granule product. Roofing roof coatings roof granules.

That tradition of innovation continues today with harsco excelling as a nimble creative partner in the development of new products to fulfill. The 3m industrial mineral products division is part of that heritage. Using 3m science in processing coating and adhesives technologies allows us to improve the performance and durability of our granules giving manufacturers a better product that will stand the test of time. All of our thermal processing equipment is engineered around the unique characteristics of the material to be processed to ensure an optimal.

Producing quality granules for the roofing industry for over 85 years. Ca prop 65 pdf. A typical process of transforming rock into roofing granule is outlined and illustrated below. Item 240789 model 4302208.

A roof containing white armor granules. Through harsco s proprietary processing techniques we have been able to deliver premium quality roofing granules that are a critical raw material used in the production of asphalt roofing shingles. White armor cool roofing granules are specifically designed for use in modified bitumen roofing applications. Check other stores closed.