Rack And Pinion Gear Ratio Calculation

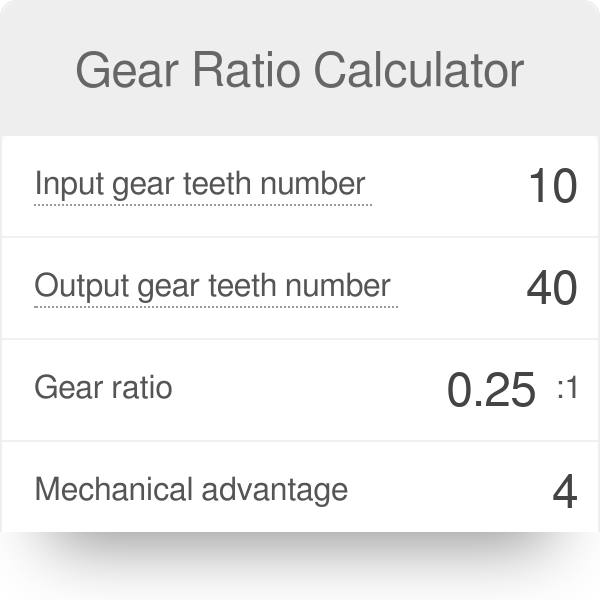

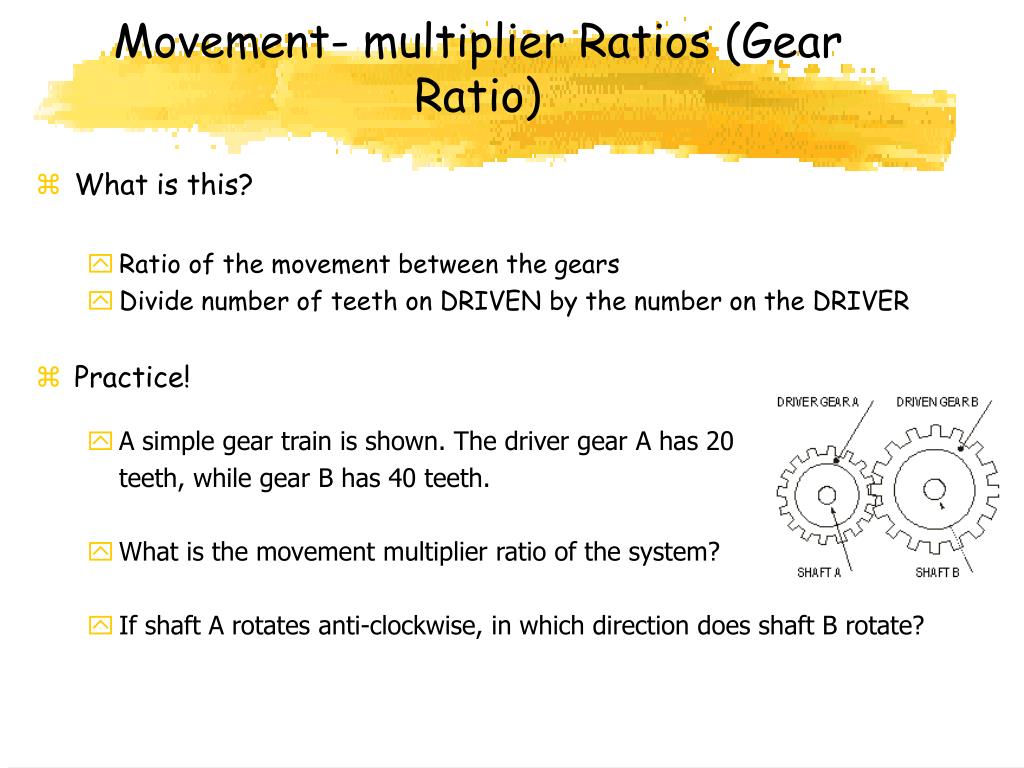

We can calculate the gear ratio of rack and pinion in the following way.

Rack and pinion gear ratio calculation. A pinion of about 20 teeth is mathematically the optimum in terms of tangential force and system backlash. This gives you a secondary gear ratio of 1 30 30 1. Calculating rack and pinion gear ratio instead of counting the number of teeth in each gear measure the distance the rack moves in inches. Take the pinion to one end of the rack.

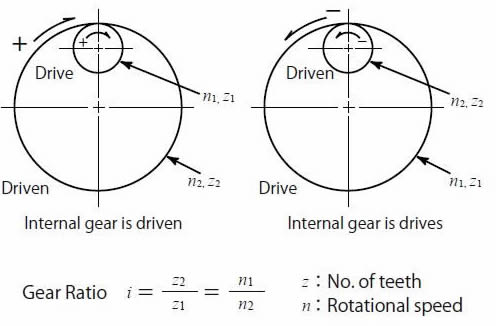

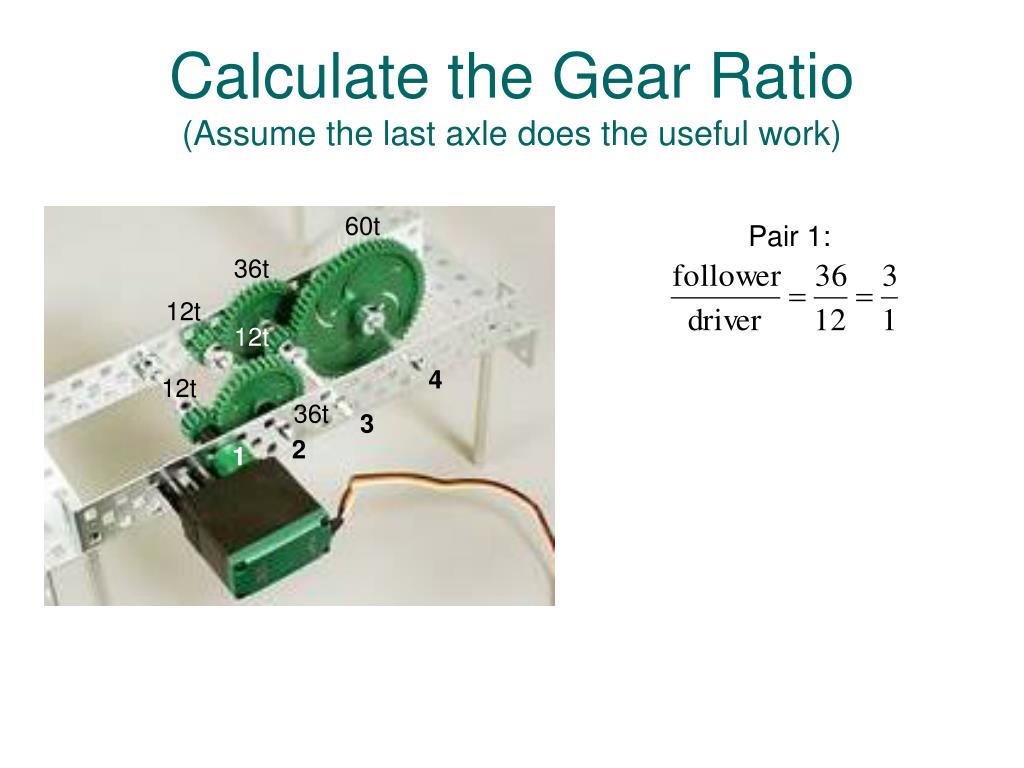

The force the rack sees. For example pinion with 18 teeth is mounted on a motor shaft and is meshed with a larger gear that has 54 teeth. Rack and pinion rack and pinion gears are used to convert rotation from the pinion into linear motion of the rack a perfect example of this is the steering system on many cars. Ring gear teeth pinion gear teeth 41 11 3 73.

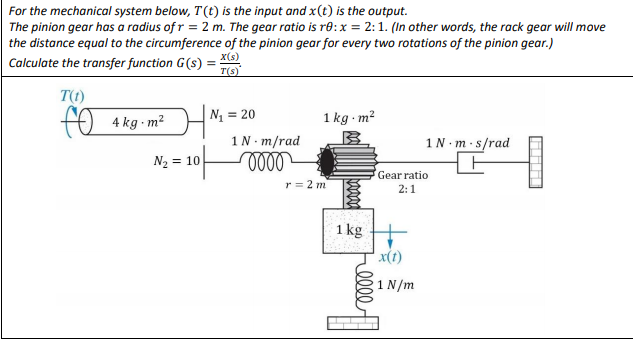

A larger pinion provides more backlash a smaller pinion can transmit lower torques and has a higher wear. 1 2012 dimensions in mm zd 3 your calculation values given travelling operation. Looking at the chart above the internal ratio is 0 55 for gear 1 and 3 3 for gear 12. Unlike ball screw sizing which must take into account factors such as characteristic and critical speeds end bearing considerations and the effects of preload in addition to basic thrust force and drive torque calculations rack and pinion drive sizing is primarily based on three factors.

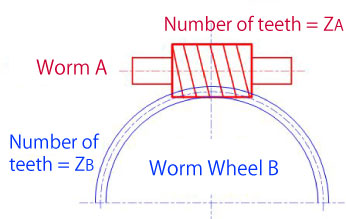

Measure the distance from the end of the rack to an arbitrary point turn the pinion one full revolution and then measure the distance again. Bevel and crown gears. Gear termi nology this is one of the easiest guides on gears. Calculate the distance travelled by the rack in inches.

You should be able to find your gear ratio listed on the axle tag however if that has gone missing you can simply count the number of teeth on each gear and divide the number of ring gear teeth by the number of pinion gear teeth. Therefore keep the following in mind. Calculating high and low rations on your gearbox. Move the pinion towards the another side of rack till it completes one full revolution.

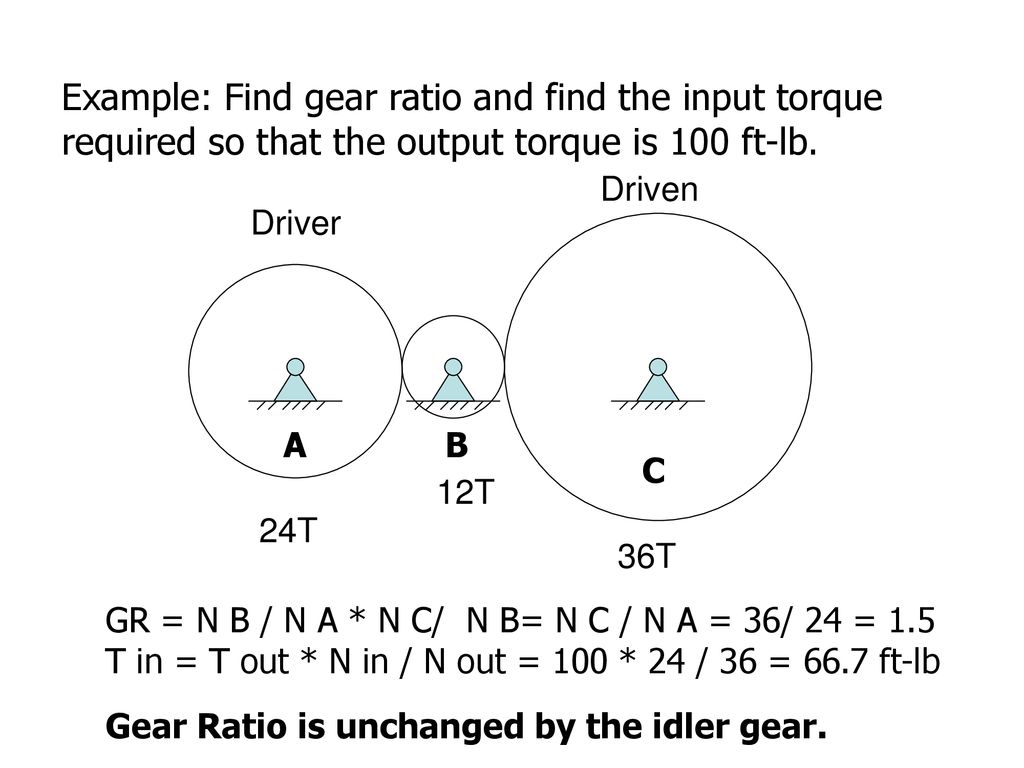

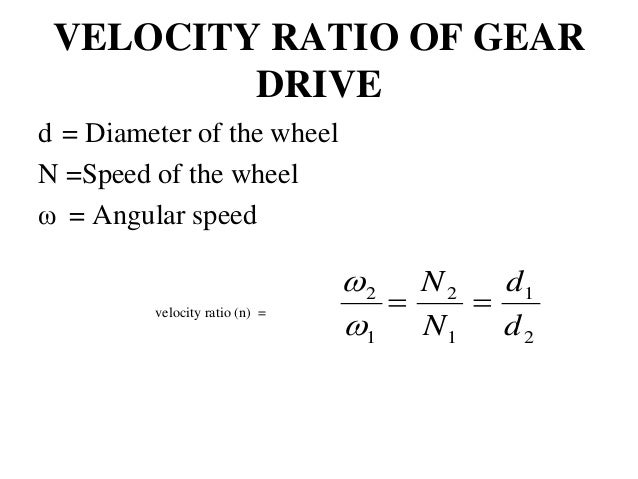

During operation the pinion makes three complete revolutions for every single revolution of the larger gear. Gear ratio calculation. Hp and e servo worm gear unit bg bevel gear unit 1 5 for unpreloaded bearings on the output shaft e g. 12 speed pinion example as an example assume you are running a 30t front sprocket and a 30t rear sprocket.

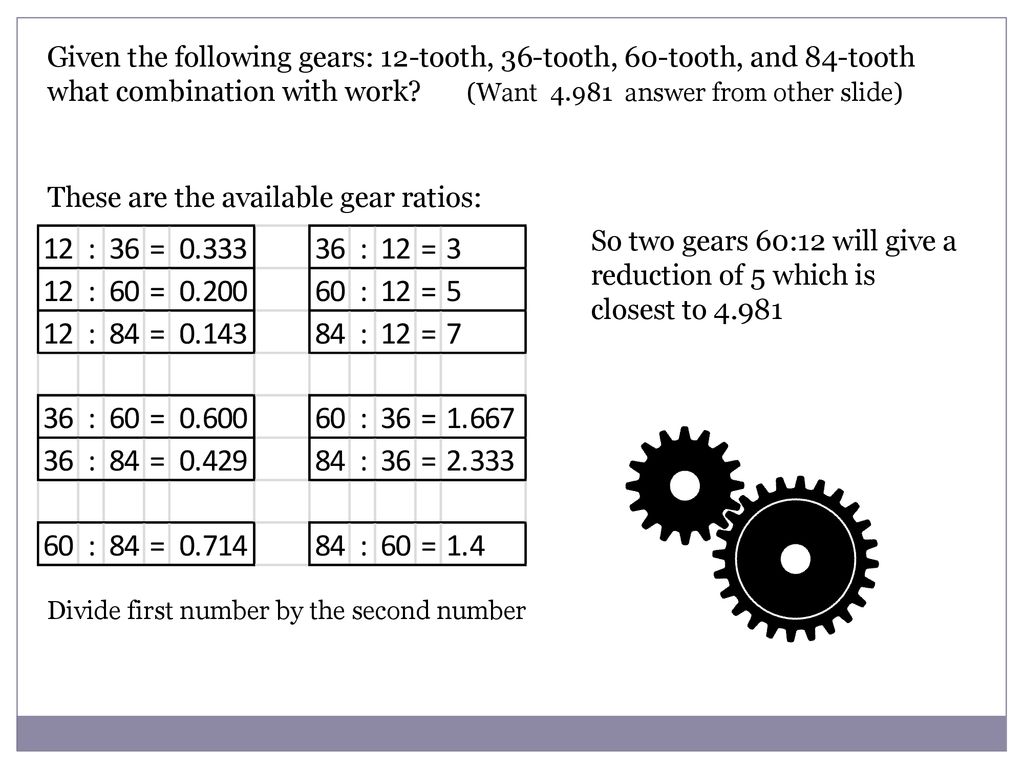

Rack and pinion drive calculation and selection. The difference between the two is the gear ratio.