Rack And Pinion Linear Motion Calculation

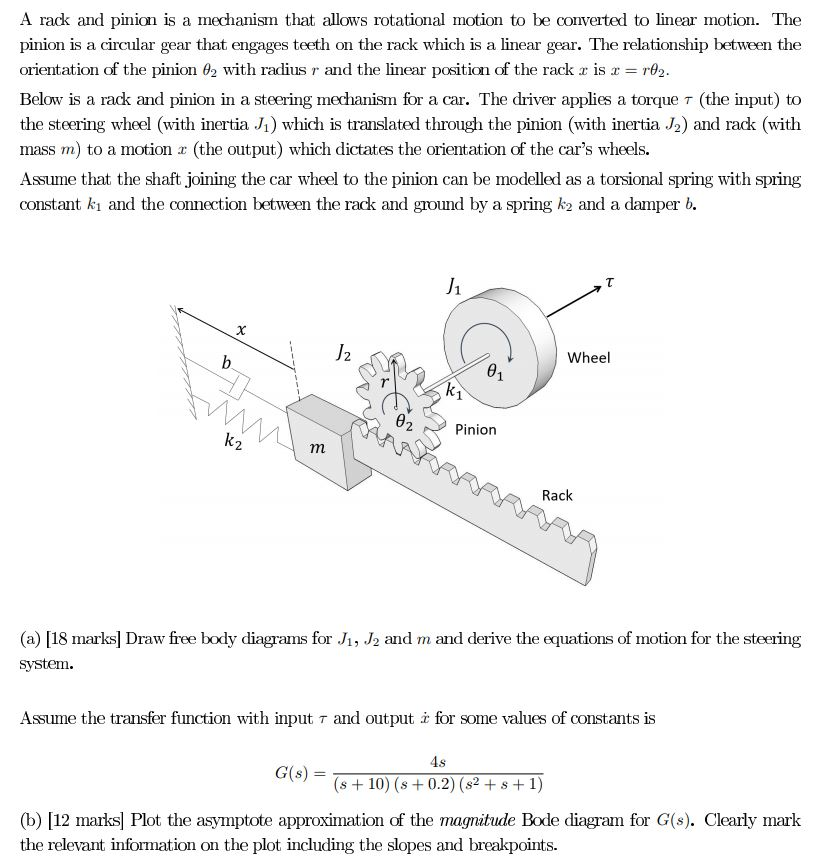

With rack and pinion steering the rotation of the pinion causes linear motion of the rack which turns the vehicle s wheels left or right.

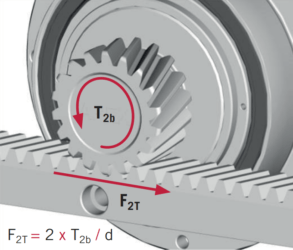

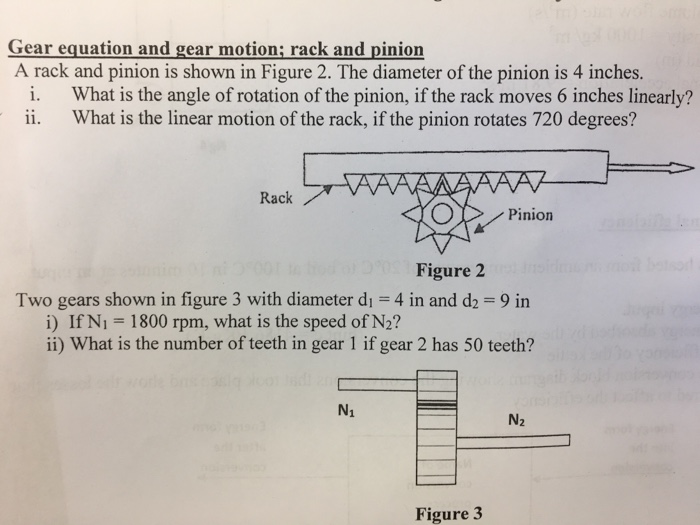

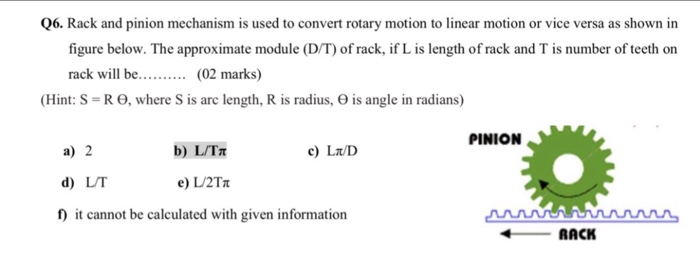

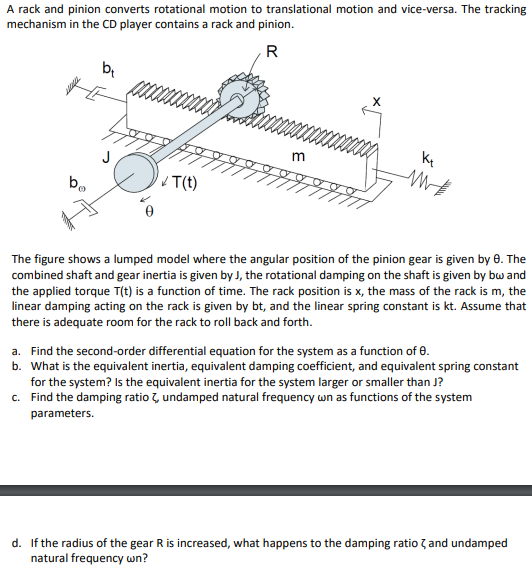

Rack and pinion linear motion calculation. This pinion engages a linear gear the rack to convert rotational motion into translational motion. A bar shaped gear with an infinite flat surface radius of a cylindrical gear is called a rack and a meshed spur gear is called a pinion. From linear deviation to hardness and straightness all tolerances can be found. Maximum rotational speed of pinion.

For a silent and low backlash drive with a long service life it is recommended to use a pinion and rack from 1 supplier. The rack s teeth are trapezoidal while the pinion has an involute tooth profile. Many gearing applications require converting rotary motion into linear motion. The most common form of this is the use of a pinion attached to a motor that then rests on a gear rack and travels back and forth depending on the direction of the motor shaft rotation.

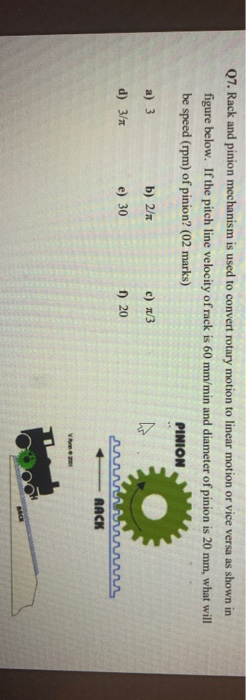

The following online calculator computes the basic dimensions and tooth profiles of a meshing rack and pinion based on the pinion s module number of teeth pressure angle usually 20 and profile shift. The tolerances especially with helical teeth are very important. Gear rack and pinion creation of linear motion. To determine the maximum rotational speed of the pinion simply divide the maximum linear speed of the application by the pinion circumference π diameter convert from millimeters to meters and convert from seconds linear speed m s or ft s to minutes rotational speed rpm.

Rack and pinion systems are a common component in railways. Another advantage for using circular pitch instead of module in these. Calculate rack and pinion. A circular gear called the pinion engages teeth on a linear gear bar called the rack.

When considering a rack and pinion for linear motion translation circular pitch is one way that you can obtain a fixed travel distance without having to use complex calculations to determine the number of rotations needed on the pinion to travel a certain distance. For some applications the motor is fixed and the rack is the object that is moving. Rotational motion applied to the pinion causes the rack to move relative to the pinion thereby translating the rotational.